Furniture Manufacturing & Export Process

Our Manufacturing & Export Process

Our furniture manufacturing and export process is built on experience, precision, and compliance. From design development and material selection to quality control and international shipping, every stage is managed in-house to ensure consistent quality, legal sourcing, and reliable delivery for global buyers.

1. Design & Product Development

Every furniture project begins with design development based on client requirements or approved models. Our team prepares technical drawings, specifications, and samples to ensure accuracy, functionality, and production feasibility before mass furniture manufacturing begins.

This includes dimension planning, construction methods, material selection guidance, and finish requirements. Prototypes or pre-production samples may be developed to validate design accuracy, functionality, and manufacturability before mass production begins.

2. Raw Material Selection & Preparation

We carefully select legally sourced and certified raw teak wood materials to meet international standards. All materials are properly conditioned and prepared to ensure stability, durability, and consistent quality throughout the production process.

Before entering production, materials undergo preparation processes such as moisture control, conditioning, and defect selection to ensure dimensional stability and reduce the risk of warping, cracking, or inconsistency during production and shipment.

3. Rough Cutting & Sizing

Raw materials are cut into required dimensions following approved production plans. This initial cutting stage ensures efficient material usage and accuracy for the next furniture manufacturing steps.

Proper sizing at this phase is essential for maintaining consistency throughout large production runs.

4. Precision Machining

Components are shaped and detailed using a combination of CNC machinery and skilled craftsmanship. This process ensures precise measurements, clean profiles, and consistency across every production batch.

Precision machining plays a key role in product durability, structural integrity, and overall visual quality.

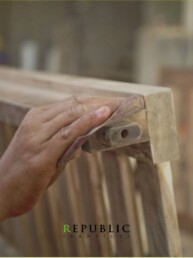

5. Surface Sanding & Refinement

After machining, all furniture components undergo multiple stages of sanding and surface refinement. This includes both machine and hand sanding to remove tool marks, smooth edges, and refine detailed areas.

The sanding process prepares surfaces for assembly and finishing, ensuring an even texture, enhanced finish adhesion, and a high-quality tactile experience for the end user.

6. Assembly & Joinery

After surface preparation, furniture components move into the assembly and joinery stage. Our craftsmen apply proven joinery techniques and controlled assembly methods to ensure structural strength, stability, and long-term durability.

Each joint is aligned and secured according to technical specifications, allowing the product to perform reliably under regular use and transportation conditions.

7. Finishing & Coating

Once assembled, furniture products enter the finishing and coating process. This stage includes staining, painting, or protective coating application based on approved finish samples.

Finishes are applied in controlled conditions to ensure consistent color, surface protection, and resistance to wear. The process also considers international safety and environmental standards, ensuring suitability for export markets.

8. Quality Control & Inspection

Quality control is conducted throughout furniture production, with a comprehensive inspection carried out before packing. Our QC team checks dimensions, construction integrity, surface finish, and overall appearance against approved specifications.

Any non-conforming items are corrected before moving to the next stage, ensuring consistent quality across each shipment.

9. Protective Packing & Labeling

Finished furniture products are packed using export-grade materials designed to protect against impact, moisture, and handling during transit. Packing methods are selected based on furniture product type, shipping method, and destination requirements.

Clear labeling is applied to support identification, handling instructions, and efficient customs processing.

10. Export Documentation & Shipping

The final stage of furniture manufacturing and exporting covers export documentation and shipping coordination. We prepare all required documents, including commercial invoices, packing lists, and manufacturer legal certificates, to ensure compliance with international trade regulations.

Our logistics team coordinates with freight partners to manage container loading, scheduling, and delivery, ensuring products arrive safely and on time at their destination.