In the competitive global furniture market, OEM furniture manufacturing plays a key role in helping international brands scale efficiently.

Through reliable OEM partnerships, brands can focus on branding and distribution while ensuring consistent quality, precise specifications, and timely production for global markets.

By working with reliable OEM furniture manufacturer, global furniture brands can focus on branding, distribution, and customer experience while ensuring their products are produced to precise specifications, timelines, and quality standards.

In this article, Republic Furniture want to explain about OEM furniture manufacturing and how the right OEM furniture partner can help your brand compete and grow internationally.

What Is OEM Furniture Manufacturing?

In the furniture industry, OEM (Original Equipment Manufacturer) refers to a manufacturing model where a producer makes furniture products based on the designs, specifications, and brand requirements of another company, which then sells the products under its own brand name.

OEM furniture manufacturing allows brands to bring their unique designs to market without owning or operating production facilities.

Unlike a regular furniture supplier, who usually sells ready-made or catalog products with limited customization, an OEM manufacturer works closely with brands to produce exclusive designs tailored to specific market needs.

While suppliers focus on selling existing products, OEM manufacturers focus on precision, consistency, and collaboration, ensuring the final furniture reflects the brand’s vision.

Is an OEM Manufacturer the Same as a Furniture Factory?

An OEM manufacturer is not the same as a regular furniture factory, they work closely with brands to produce furniture based on specific designs, quality standards, and branding requirements.

OEM manufacturing emphasizes customization, collaboration, and consistency, making it a more strategic and brand-focused solution than a traditional factory.

How is the OEM Furniture Manufacturing Process in Indonesia?

Here are the key steps involved in the OEM furniture manufacturing process in Indonesia. Let’s take a closer look.

1. Accepting Designs and Specifications from the Brand

OEM furniture manufacturers begin by receiving detailed designs, technical drawings, and product specifications directly from the brand.

This ensures that every furniture piece is produced according to the brand’s exact requirements, including dimensions, construction methods, finishes, and functional details.

2. Material Selection (Solid Wood, Teak, Mahogany, Rattan, etc.)

The manufacturer carefully selects suitable materials based on the brand’s design, performance standards, and target market.

This may include solid wood such as teak or mahogany, as well as natural materials like rattan, ensuring durability, aesthetics, and compliance with sustainability or legality requirements.

3. Prototyping & Sampling

Before mass production begins, prototypes or samples are created to validate design accuracy, comfort, structure, and finishing quality.

This stage allows brands to review, test, and approve the product, ensuring it meets expectations before full-scale manufacturing.

4. Mass Production

Once the sample is approved, the OEM manufacturer proceeds with mass production.

This process follows standardized workflows and production schedules to maintain consistency, efficiency, and timely delivery while meeting the agreed order volume.

5. Quality Control

Quality control is conducted at multiple stages of production to ensure each piece meets the brand’s quality standards.

This includes checking materials, construction, finishing, and overall workmanship to minimize defects and ensure consistency across all units.

6. Export-Ready Packaging

Finished furniture is packed using export-standard packaging designed to protect products during international shipping.

This includes proper wrapping, labeling, and carton or crate specifications to ensure safe delivery and compliance with global logistics requirements.

OEM vs ODM Furniture Manufacturing: Key Differences

In the furniture industry, OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) represent two different production approaches.

Under the OEM model, the buyer provides the custom furniture design, specifications, and brand requirements, while the manufacturer focuses on producing the products exactly according to those guidelines.

In contrast, ODM allows the manufacturer to provide ready-made or semi-custom furniture designs that buyers can select and brand as their own.

The choice depends on the buyer’s market strategy, design capability, budget, and desired level of product uniqueness.

Why Indonesia Is a Preferred OEM Furniture Manufacturing Hub for Global Brands?

Indonesia has become a preferred OEM furniture manufacturing hub for global brands by combining skilled craftsmanship, making it a strategic destination worth exploring further.

Here are the key reasons behind this growing preference:

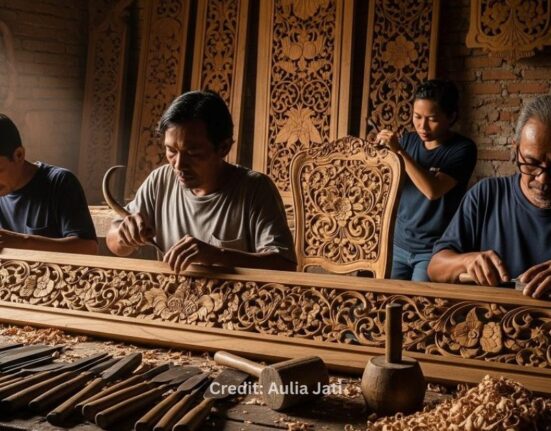

1. Skilled Craftsmanship (Jepara, Java, and Other Regions)

Indonesia is renowned for its skilled furniture craftsmanship, particularly in regions such as Jepara and across Java.

Artisans combine handcraft techniques with modern production methods, resulting in furniture that offers refined detailing, strong construction, and consistent quality suitable for global markets.

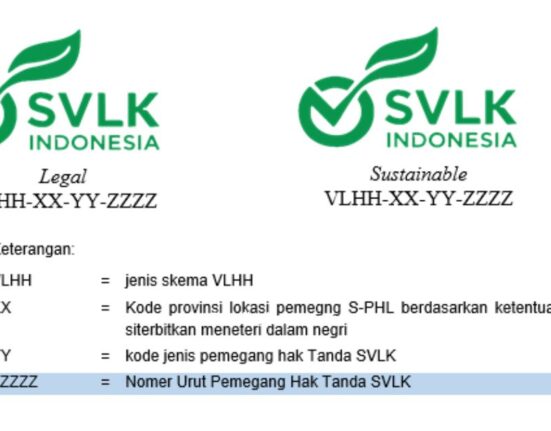

2. Sustainable Wood & Legal Compliance

Indonesia has a strong commitment to sustainable forestry and legal wood sourcing, supported by systems such as SVLK.

OEM manufacturers work with certified materials and documented supply chains, giving global brands confidence that their furniture meets international legality, sustainability, and ethical sourcing requirements.

3. Flexibility in Customization & Low MOQ (Compared to China and Vietnam)

Indonesian OEM furniture manufacturers are known for their flexibility in handling custom designs and lower minimum order quantities.

Compared to China or Vietnam, this allows brands to test new products, manage inventory risks, and develop exclusive collections without committing to large-scale orders.

4. Cost Efficiency Balanced with Quality

Indonesia offers a competitive balance between cost efficiency and product quality.

Brands benefit from skilled labor, locally sourced materials, and efficient production processes, resulting in furniture that delivers strong value.

Types of Furniture Produced Under OEM Furniture Manufacturing

OEM furniture manufacturing covers a wide range of product categories designed to meet diverse market needs, including the following types of furniture produced for global brands.

Here is types of furniture produced under OEM furniture manufacturing:

1. Outdoor Furniture

OEM manufacturers produce outdoor furniture designed to withstand various weather conditions while maintaining aesthetic appeal.

This includes the use of durable materials such as teak, synthetic wicker, and weather-resistant finishes, making the products suitable for gardens, patios, resorts, and commercial outdoor spaces.

2. Indoor Furniture

Indoor furniture under OEM manufacturing covers a wide range of products, including living room, dining, bedroom, and storage furniture.

Manufacturers focus on precise construction, fine finishing, and material quality to ensure comfort, durability, and alignment with the brand’s design and market positioning.

3. Hospitality & Contract Furniture

OEM furniture for hospitality and contract projects is produced to meet higher durability and safety standards.

This category includes furniture for hotels, resorts, restaurants, offices, and public spaces, where consistency, long-term performance, and compliance with commercial requirements are essential.

4. Custom Furniture for Retail Brands

Custom OEM furniture is developed specifically for retail brands that require exclusive designs and brand-specific specifications.

Manufacturers work closely with buyers to create unique collections, allowing brands to differentiate their products while maintaining consistent quality across multiple production runs.

Furniture OEM Certificate & Compliance

To ensure quality, legality, and smooth international trade, OEM furniture manufacturing is supported by essential certifications and compliance standards that global buyers should understand.

Here is furniture OEM certification and compliance:

1. FSC / SVLK / Legal Wood Compliance

OEM furniture manufacturers ensure that all wood materials are sourced legally and responsibly through certifications such as FSC and SVLK.

These systems verify the legality and traceability of timber, helping global buyers meet sustainability requirements and comply with international import regulations.

2. Quality Standards

To meet global market expectations, OEM manufacturers follow strict quality standards throughout the production process.

This includes material inspection, structural testing, finishing checks, and final product evaluation to ensure consistency, durability, and compliance with buyer specifications.

3. Export Documentation

OEM manufacturers provide complete furniture export documentation required for international shipping. This typically includes commercial invoices, packing lists, certificates of origin, and, where applicable, FLEGT licenses or other regulatory documents to ensure smooth customs clearance in the destination country.

4. Packaging & Shipping Standards

Furniture is packed according to international packaging and shipping standards to protect products during transit.

This involves appropriate wrapping, labeling, carton or crate construction, and container loading methods to minimize damage and ensure safe delivery to global markets.

Who Should Use OEM Furniture Manufacturing?

OEM furniture manufacturing is best suited for businesses that require tailored designs, consistent quality, and scalable production, making it an ideal solution for the following types of buyers.

1. Furniture Brands

OEM furniture manufacturing allows furniture brands to produce exclusive designs while maintaining full control over product specifications, quality standards, and brand identity.

This model supports long-term brand development and consistent product offerings across different markets.

2. Wholesalers & Importers

Wholesalers and importers benefit from OEM manufacturing by sourcing customized furniture in bulk at competitive costs.

OEM partners help ensure consistent quality, reliable supply, and compliance with export regulations, reducing risks in international trade.

3. Hotel & Project Buyers

Hotels, resorts, and project-based buyers use OEM furniture manufacturing to obtain furniture tailored to specific design themes, functional needs, and durability requirements.

This ensures uniformity, long-term performance, and compliance with hospitality and contract standards.

4. E-Commerce Furniture Brands

OEM manufacturing supports e-commerce furniture brands by offering customization, scalable production, and flexible order quantities.

This enables online brands to launch unique collections, manage inventory efficiently, and respond quickly to changing market trends.

How to Find a Reliable OEM Furniture Manufacturing Partner in Indonesia?

Finding a reliable OEM furniture manufacturing partner in Indonesia requires careful evaluation of quality, compliance, and long-term collaboration factors that can directly impact your brand’s success.

1. Manufacturing Experience & Portfolio

A reliable OEM furniture manufacturer should have proven experience and a strong portfolio showcasing past projects and export markets.

Reviewing their product range, craftsmanship, and previous collaborations helps buyers assess whether the manufacturer can meet design complexity, volume requirements, and international quality expectations.

2. Material Sourcing Transparency

Transparency in material sourcing is essential to ensure legality, sustainability, and consistent quality.

Trusted OEM partners clearly document the origin of their wood and materials, provide relevant certifications, and maintain traceable supply chains that comply with global regulations.

3. QC System & Export Readiness

An established quality control system indicates the manufacturer’s ability to deliver consistent results.

Reliable OEM manufacturers conduct inspections at multiple production stages and are fully prepared with export documentation, packaging standards, and logistics coordination for international shipments.

4. Communication & Production Lead Time

Clear communication and realistic production lead times are critical for smooth collaboration.

A dependable OEM partner maintains responsive communication, provides regular production updates, and commits to agreed timelines to support efficient planning and on-time delivery.

OEM Furniture Manufacturing with an Indonesian Furniture Manufacturer: Republic Furniture

Partnering with an Indonesian OEM furniture manufacturer like Republic Furniture gives global brands access to skilled craftsmanship, responsible material sourcing, and export-ready production under one trusted partner.

Republic Furniture as trusted Indonesia furniture manufacturer from Jepara since 1999 works closely with buyers to produce Indonesia teak furniture based on precise designs and specifications, supported by strict quality control, legal wood compliance, and flexible production capabilities.

With proven experience serving international markets, Republic Furniture offers reliable communication, consistent quality, and a commitment to long-term partnerships, making it a dependable choice for brands seeking a trusted OEM furniture manufacturing partner in Indonesia.

Source:

- https://furnigenius.com/what-is-oem-in-furniture-advantages-disadvantages/

- https://auroracraft.com.vn/blog/tips-and-advance/oem-vs-odm-understanding-the-difference-in-furniture-manufacturing/

- https://en.wikipedia.org/wiki/Original_equipment_manufacturer