Jepara has long been recognized as the center of Indonesia’s furniture craftsmanship, where tradition, skill, and artistry come together to create furniture of exceptional quality.

Renowned for its master woodcarvers and generations of experienced artisans, Jepara plays a vital role in shaping the identity of Indonesian furniture manufacturing.

From solid teak wood selections to intricate hand-carved details, the craftsmanship rooted in Jepara reflects a deep cultural heritage.

Not only the wood details, Jepara Furniture’s strong commitment to excellence continues to attract buyers from both domestic and international markets.

What Is Jepara Furniture Craftsmanship?

Jepara furniture craftsmanship refers to the traditional yet continuously evolving art of furniture making that originates from Jepara, Central Java.

It is characterized by a strong emphasis on hand-crafted techniques, detailed wood carving, and the use of high-quality solid wood.

The artisans combine time-honored carving methods with modern woodworking technologies to achieve both artistic beauty and structural durability.

Also Read: How to Buy Furniture from Indonesia: Where to Buy & Complete GuideThe History of Jepara Wood Carving Tradition

The history of Jepara wood carving tradition dates back centuries and influenced by Javanese, Hindu-Buddhist, and later Islamic artistic traditions as a refined form of craftsmanship used to decorate palaces, mosques, and noble residences.

Today, this long-standing tradition continues to thrive, blending historical motifs with modern interpretations while preserving the cultural values and artistic excellence that define Jepara furniture craftsmanship.

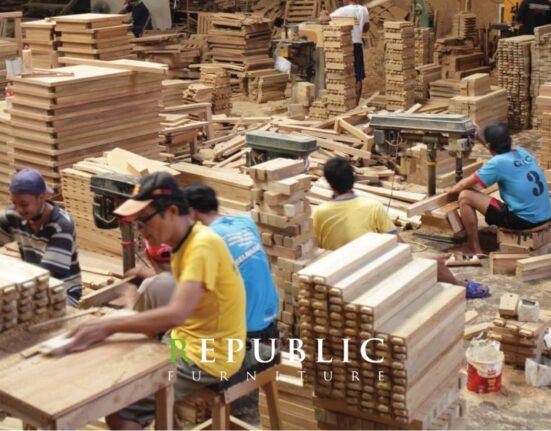

Skilled Jepara Artisans Behind Jepara Furniture

The excellence of Jepara furniture is inseparable from the skill and dedication of the local artisans who are known for their precision, patience, and deep understanding of wood characteristics, particularly teak.

This combination of heritage craftsmanship and contemporary expertise enables Jepara furniture to remain competitive in global markets while maintaining its reputation for authenticity, quality, and timeless craftsmanship.

Jepara Furniture Manufacturing Process

The Jepara furniture manufacturing process begins with the careful selection of raw wood, primarily high-quality teak known for its strength, durability, and natural resistance to pests.

Here the following points that explain every step of the Jepara furniture manufacturing process from raw to finished product:

1. Wood Selection & Material Preparation

The manufacturing process of Jepara furniture begins with strict wood selection and material preparation with high-quality solid wood, most commonly teak, is carefully chosen based on age, grain pattern, density, and overall condition.

After selection, the wood is cut into rough components, sorted according to size and function, so that each furniture part meets structural requirements before moving to the next process.

2. Wood Drying & Moisture Control

Proper wood drying is a critical step in producing durable Jepara furniture that includes the prepared wood undergoes air-drying or kiln-drying to reduce moisture content to an optimal level.

Well-dried wood not only improves durability but also allows for more precise carving, stronger joints, and a smoother finishing result.

3. Hand Carving & Shaping

Hand carving and shaping represent the artistic core of Jepara craftsmanship which skilled artisans use traditional tools and techniques to carve intricate motifs, smooth contours, and refined details directly into the solid wood.

Each carving is done by hand, making every piece unique while maintaining consistency in quality and design accuracy.

Also Read: Comprehensive Guide to Import Furniture from Indonesia4. Assembly & Construction

Once all components are shaped and carved, the furniture enters the assembly and construction stage.

Artisans carefully join each part using strong, time-tested joinery techniques that enhance structural integrity without compromising aesthetics.

5. Finishing & Quality Control (natural, aesthetic, custom)

The final stage is finishing and quality control, where Jepara furniture achieves its complete visual and functional appeal.

Through careful finishing and strict quality control, Jepara furniture delivers natural beauty, refined aesthetics, and customizable results that meet global market expectations.

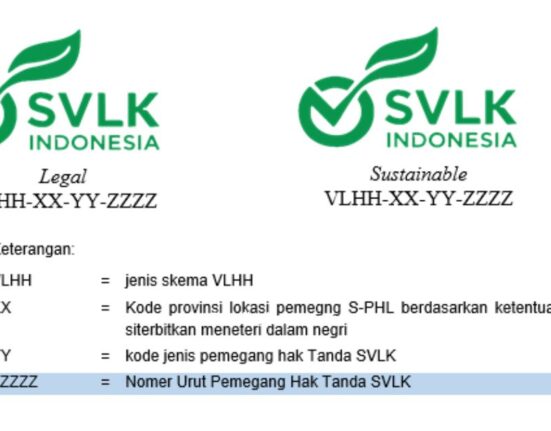

Premium Materials & Sustainable Wood Sourcing

To ensure long-term availability and environmental responsibility, the wood is sourced from legally managed and sustainable forests, often supported by government regulations and certification systems.

By combining premium raw materials with sustainable practices, Jepara furniture offers lasting value, environmental accountability, and products that meet international standards while supporting ethical and responsible furniture manufacturing.

Custom Furniture Expertise from Jepara

Jepara manufacturers and artisans are highly experienced in producing made-to-order furniture based on specific dimensions, materials, finishes, and design styles requested by clients.

Supported by skilled craftsmanship, Jepara’s custom furniture production delivers personalized solutions that combine aesthetic appeal, durability, and authentic Indonesian craftsmanship.

Why Global Buyers Trust Jepara Furniture Craftsmanship

Jepara furniture craftsmanship has consistent commitment to quality, authenticity, and long-term value where they understand global design preferences, quality benchmarks, and export regulations.

Supported by strict quality control, customization capabilities, and reliable production processes, Jepara furniture has become a preferred choice for residential, hospitality, and commercial projects worldwide.

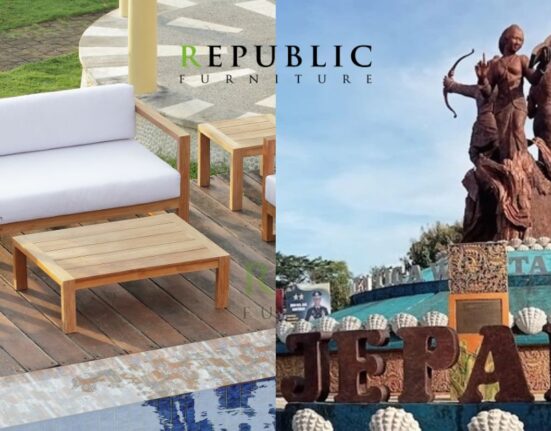

Choosing the Right Jepara Furniture Manufacturer: Republic Furniture

As an experienced Jepara furniture manufacturer, Republic Furniture combines skilled local artisanship with strict quality control, premium material selection, and sustainable wood sourcing to deliver furniture that meets international standards.

With a commitment to premium materials, skilled artisans, and reliable export services, Republic Furniture provides a trusted gateway to sourcing high-quality Jepara furniture for global markets.

Visit the Republic Furniture website to learn more, view available designs, and begin a partnership built on craftsmanship, credibility, and lasting value.

Source:

- https://qualiteak.com/why-indonesian-teak-wood-furniture-is-very-popular/

- https://www.auliajati.com/articles/indonesia-furniture-and-its-popularity/

- https://asiafurniture.id/indonesia-furniture/why-choose-indonesian-furniture/