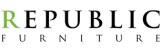

Teak furniture manufacturing process at Republic Furniture is a carefully structured steps that combines high-quality raw materials, skilled craftsmanship, and modern production techniques to deliver durable and elegant products. Each stage, from teak selection to final finishing, is designed to ensure consistency, strength, and long-lasting beauty.

This article provides a detailed explanation of every stage involved in the teak furniture manufacturing process at Republic Furniture as leading Indonesian furniture manufacturer established from 1999, highlighting material selection, production techniques, and quality control measures.

Overview of Our Teak Furniture Production Process

How does Republic Furniture ensure the quality of each production process? Republic Furniture is committed to delivering high-quality teak furniture by maintaining strong craftsmanship, precision, and strict quality control at every stage of production.

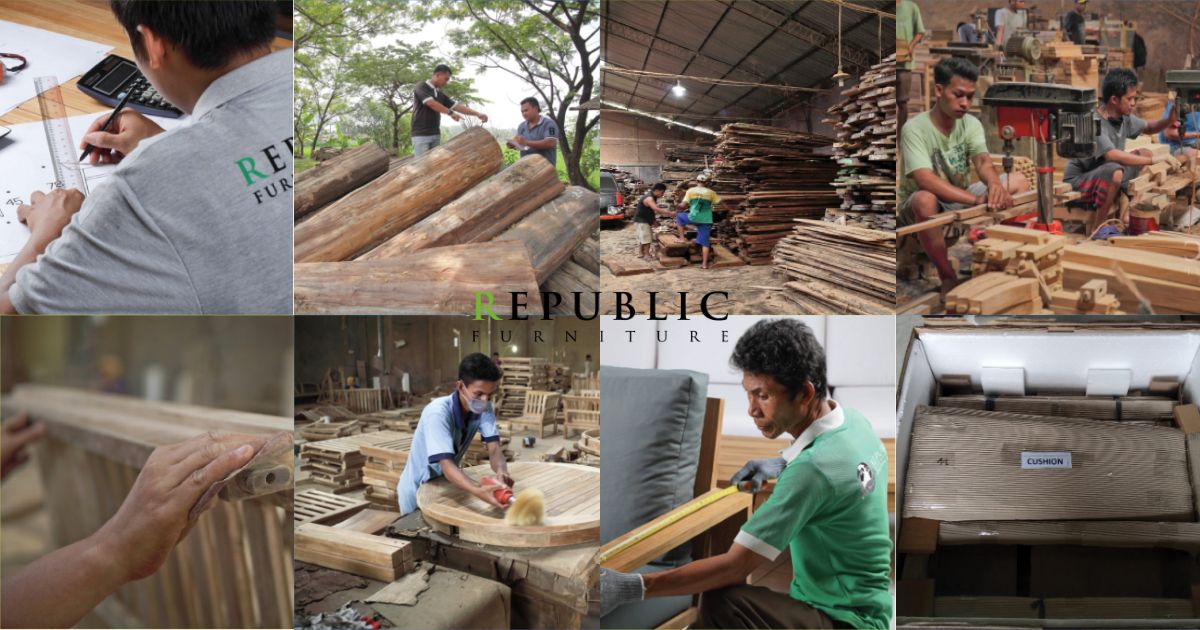

Based in Jepara, Indonesia, an area well known for its rich woodworking heritage and generations of skilled craftsmen, the company combines traditional handcrafting techniques with well-organized and modern manufacturing processes.

This balanced approach allows Republic Furniture to consistently produce teak furniture that reflects both timeless design and reliable quality.

Step-by-Step Teak Furniture Manufacturing Process

What are the steps in teak furniture manufacturing? The following section provides a comprehensive explanation of each stage involved in the teak furniture manufacturing process at Republic Furniture.

1. Design & Product Development

The process begins with design and product development, where furniture concepts are created based on market trends, customer requirements, and functional needs. Detailed drawings, technical specifications, and prototypes are developed to define dimensions, structure, joinery methods, and finishing standards.

This stage ensures that the final product meets both aesthetic and practical expectations.

Also Read: 10 Strengths of Republic Furniture Over Other Furniture Factories2. Material Selection & Wood Conditioning (Containment)

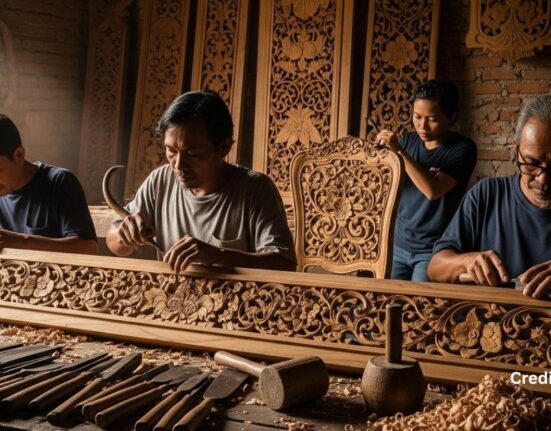

High-quality teak wood is carefully selected based on grain pattern, moisture content, and structural integrity. The wood then undergoes a conditioning or containment process, where it is properly seasoned and stabilized to reduce moisture levels.

This step is critical to prevent cracking, warping, or shrinkage during later stages of production.

3. Rough Cutting into Basic Components

How is teak wood processed? Conditioned teak wood is cut into rough sizes according to the design specifications. Large boards and logs are broken down into basic components such as legs, frames, panels, and supports.

This stage focuses on efficient material usage while maintaining sufficient allowance for further shaping and machining.

4. Machining & Shaping Precision

Rough components are processed through precision machinery to achieve accurate dimensions and smooth profiles. Operations such as planing, routing, drilling, and joint formation are performed to ensure proper fit and structural strength. Skilled operators closely monitor this stage to maintain consistency and accuracy.

5. Sanding & Surface Preparation

All components undergo thorough sanding to remove machining marks and surface imperfections. Multiple sanding stages, from coarse to fine grit, are applied to achieve a smooth and even surface. Proper surface preparation is essential for enhancing the appearance of the wood and ensuring optimal adhesion during finishing.

6. Finishing Process

The finishing stage enhances the natural beauty of teak while providing protection against moisture, stains, and wear. Finishing methods may include staining, oiling, sealing, or coating, depending on product requirements. Each layer is carefully applied and dried to achieve uniform color, texture, and durability.

Also Read: 10+ Guide to Choose Best Teak Furniture Manufacturer7. Quality Control & Inspection

Before packing, each furniture piece undergoes strict quality control inspections. Checks include dimensional accuracy, joint strength, surface finish, color consistency, and overall workmanship. Any defects identified are corrected to ensure that only products meeting Republic Furniture’s quality standards are approved for delivery.

8. Packing & Export Preparation

Approved products are carefully packed using protective materials to prevent damage during transportation. Packaging is designed to meet export standards, ensuring safety during handling and long-distance shipping. Proper labeling and documentation are completed to support smooth export and delivery to international markets.

Republic Furniture stands as a trusted teak furniture manufacturer based in Indonesia, offering premium outdoor and indoor collections, combining skilled craftsmanship, precise manufacturing processes, and strict quality control at every stage of production.

With its strong roots in Jepara’s renowned woodworking tradition and a commitment to excellence, the company consistently delivers furniture that is durable, functional, and timeless in design.

By choosing Republic Furniture, you can be confident to invest in high-quality teak furniture crafted with care, reliability, and long-term value.