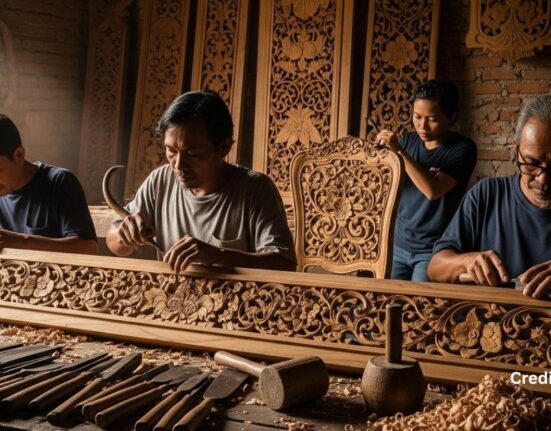

Furniture plays a vital role in enhancing the functionality of homes and workplaces, but few consider how furniture is made before it reaches the end user. The furniture manufacturing process is a structured journey that transforms raw materials into durable, finished products through skilled craftsmanship and industrial precision.

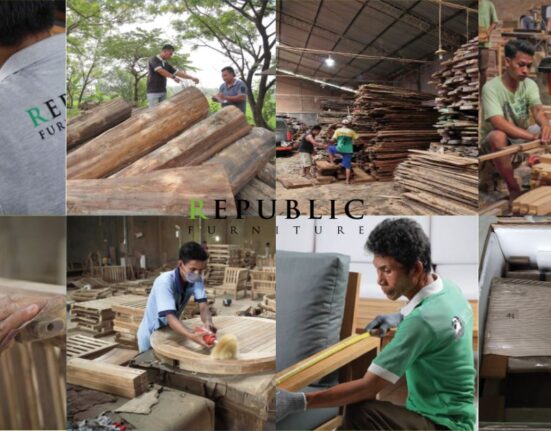

In this article, we want to explore how high-quality furniture is produced and highlight the contribution of Republic Furniture, a leading teak furniture manufacturing company in Jepara, Indonesia.

Furniture Manufacturing Stages & Process

What are the steps in furniture manufacturing? Furniture manufacturing is the process of creating functional and visually appealing products by designing, cutting, shaping, joining, finishing, and assembling materials such as wood, metal, plastic, and glass.

Below are the detail of important furniture manufacturing processes involved in transforming raw materials into functional and high-quality furniture:

1. Product Design and Development

This initial furniture manufacturing process focuses on translating ideas and functional requirements into detailed furniture designs. Designers create technical drawings, dimensions, and material specifications while considering aesthetics, ergonomics, durability, and manufacturing feasibility.

Prototypes may also be developed to test functionality and refine the design before mass production begins.

2. Raw Material Selection and Wood Treatment

At this stage, suitable raw materials such as solid wood, engineered wood, or other components, are carefully selected based on strength, stability, and intended use to making wooden furniture.

Wood treatment processes, including drying, kiln-drying, and chemical treatments, are applied to reduce moisture content, prevent insect infestation, and enhance long-term durability furniture.

Also Read: 10+ Guide to Choose Best Teak Wood for Furniture (Especially Outdoor)3. Rough Cutting into Basic Components

The selected materials are cut into basic shapes and sizes according to the design specifications. This rough cutting process prepares the wood for further refinement while minimizing waste and ensuring consistency across components of furniture.

4. Precision Machining and Component Shaping

During this stage, advanced machinery and skilled craftsmanship are used to shape individual components accurately. Processes such as milling, drilling, turning, and joinery are performed to achieve precise dimensions and ensure that all parts fit together properly during assembly.

5. Surface Sanding and Refinement

Sanding is conducted to smooth the surface of each component and remove tool marks or imperfections. This step enhances the texture and appearance of the furniture while preparing the surface for finishing materials to adhere evenly.

6. Finishing and Surface Protection

Finishing involves applying coatings such as stains, paints, varnishes, or oils to improve appearance and protect the furniture from moisture, wear, and environmental damage. This process enhances color, highlights wood grain, and contributes to the overall aesthetic and durability of the product.

7. Quality Control & Inspection

Quality control ensures that the finished furniture meets design standards and industry requirements. Each piece is inspected for structural integrity, surface quality, dimensional accuracy, and finishing consistency. Any defects are corrected before the product proceeds to the final stage.

Also Read: 7 Guide to Choose Best Teak Furniture That Lasts for Years8. Packaging and Shipping Preparation

The final stage involves securely packaging the furniture to prevent damage during storage and transportation. Protective materials and proper labeling are used to ensure safe handling and efficient delivery to distributors or customers.

Understanding how furniture is made with furniture manufacturing process highlights the level of precision, expertise, and quality control required to produce durable and functional furniture.

Each stage plays an essential role in ensuring that raw materials are transformed into well-crafted products that meet industry standards and consumer expectations.

By recognizing these processes, we can better appreciate the value of professionally manufactured furniture and make more informed decisions when selecting furniture for long-term use.